- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Mexico is located near the equator, with an average temperature of over 20 ℃ throughout the year, and the highest temperature in summer to 45 ℃. The hot climate has led to a continuous increase in demand for locally consumed ice cups and bag ice.

Our Mexico client captured this market opportunity and immediately partnered with Icemedal Refrigeration to build a 10 ton daily tube ice factory. According to the customer's explicit request, the production line of ice factory is equipped with a fully automatic packaging system.

The tube ice machine of Icemedal Refrigeration uses food grade materials in all areas in contact with water and ice tubes.

We can see that the produced tube ice has no bubbles, no cracks, and a smooth end face,the transparency ≥ 90%.

Based on the existing factory building and daily production standard of 10 tons of Mexico customers, Icemedal's technical team has specially designed a complete tube ice production line solution covering water purification, ice making, de icing, ice screening, packaging and cold storage for them.

The automated packaging production line is an upgraded version of the previous manual packaging, aimed at improving the production efficiency of the ice tube factory and saving overall labor costs.

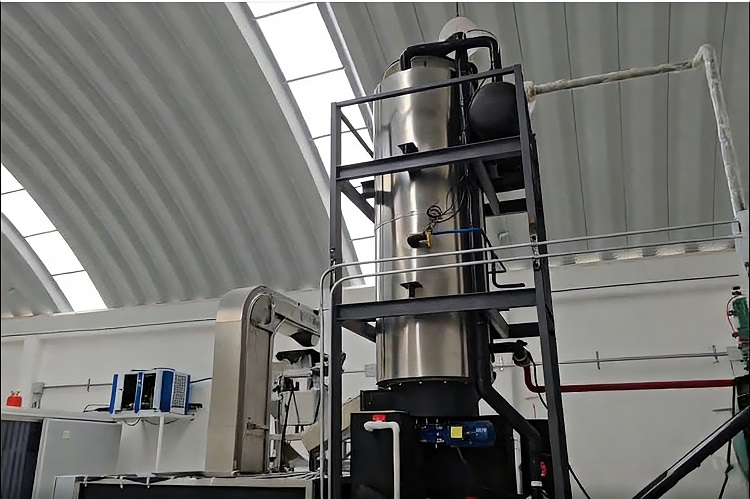

Due to the limited space of the customer's ice factory, it is very important to design the ice tube machine and pipeline layout in a reasonable manner according to the customer's ideas.

As shown in the picture, you can see the placement and pipeline design of the ice machine in the customer's factory, which combines the advantages of cost control and aesthetics. At the same time, according to the request of the Mexico customer, we have changed the brand logo of the ice tube machine to the brand name of the customer's factory.

Before handing over to the customer, each tube ice machine of Icemedal Refrigeration will undergo quality checks such as pressure maintenance testing, refrigerant pipeline sealing testing, normal oil level testing and fault protection testing. Not only that, records and tests will be conducted on the condition of ice cubes, the amount of ice produced per unit time and the time of word ice production to ensure compliance.

At the request of the Mexico customer, the technical engineer of Icemedal Refrigeration went to the Mexican customer's factory for on-site installation and guidance.

From a 10 ton tube ice machine to customized delivery of a complete production line, the 10 ton ice plant project of a Mexico customer demonstrates the technical and delivery capabilities of Icemedal Refrigeration in the commercial ice making industry.