- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| The 15ton integrated tube ice machine can produce up to 150000kgs of ice per day, which can meet large-scale ice demand. It has high ice-making efficiency and short ice-making cycle. MOQ:1 set Payment:T/T, Western Union, MoneyGram, L/C Lead Time:45 days after getting down payment Certification:CE Place of Origin:Hunan, China (Mainland) Shipping Port:Guangzhou, China or as your request(Mainland,China) Warranty:1 year After-sales Service Provided:Engineers available to service overseas | |||||||||

IMT15

Icemedal

The 15-ton integrated tube ice machine has become an ideal ice-making solution for many industries due to its high efficiency, low energy consumption, and easy maintenance. If you are looking for an ice-making equipment that can meet large capacity requirements and has energy-saving and environmental protection,15ton Integrated tube ice maker machine will be a good choice.

| Icemedal Integrated Tube Ice Machine Features:

1.Integrated Design: It adopts a compact integrated design that integrates ice making, ice storage and transportation functions, greatly saving plant space and simplifying the installation process.

2.Customization Service: We supports the adjustment of ice tube sizes of various specifications to meet the special needs of different industries. At the same time, additional services such as customized appearance design and logo printing can also be provided according to customer needs.

3.Better ice quality :Tube ice is more uniform and less crushed ice

4.Smaller space :Less shipping costs and constructing costs, The 15ton intedrated tube ice maker floor space is usually reduced by 30%~50% compared to split-type equipment

5. Easier installation (Less installing time and costs, reduce the risk of damage due toimproper operation)

| Integrated Tube Ice Machine Parameters

| Model | IMT5 | IMT10 | IMT15 | IMT20 | IMT30 |

Ice output | 5t/24hrs | 10t/24hrs | 15t/24hrs | 20t/24hrs | 30t/24hrs |

| lce tube diameter | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional |

| Cooling Capacity | 52.5kw | 82kw | 123.9kw | 165.2kw | 247.8kw |

| input power | 20.95kw | 37.2kw | 51.9kw | 64.5kw | 106.8kw |

| Compressor input power | 17.3kw | 31.9kw | 45.2kw | 52.8kw | 102.6kw |

| lce cut reducer input power | 0.75kw | 0.75kw | 1.5kw | 1.5kw | 2.2kw |

| Water pump input | 1.1kw | 1.5kw | 2.2kw | 2.2kw | 4kw |

| Ice machine Weight | 1600kg | 2750kg | 4000kg | 4800kg | 6200kg |

| Ice Machine Size | 1800*1620*2450 | 2400*2250*3200 | 2400*2250*4200 | 2500*2250*5437 | 2500*2250*6090 |

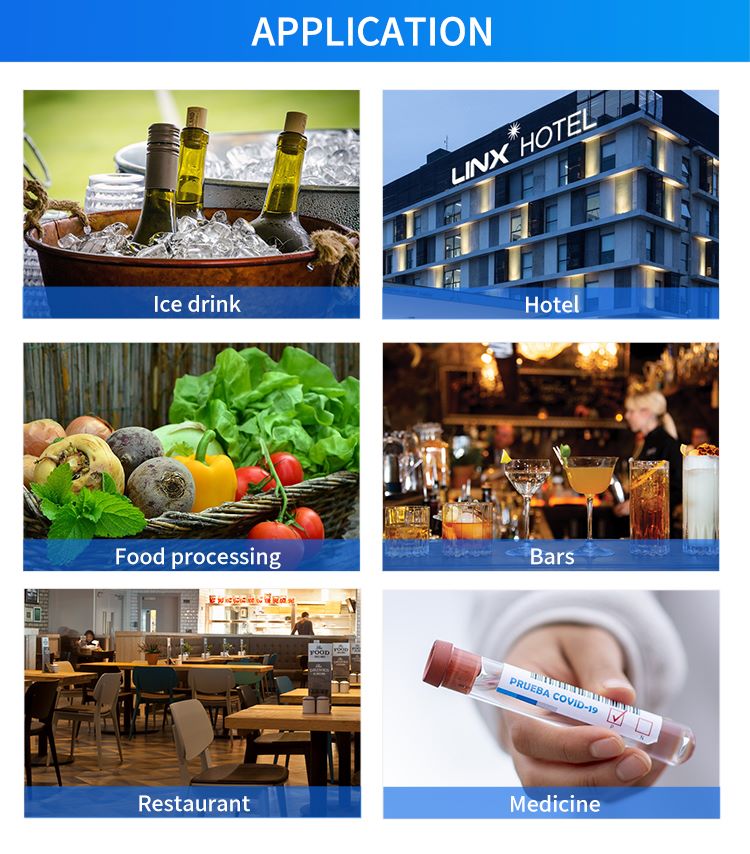

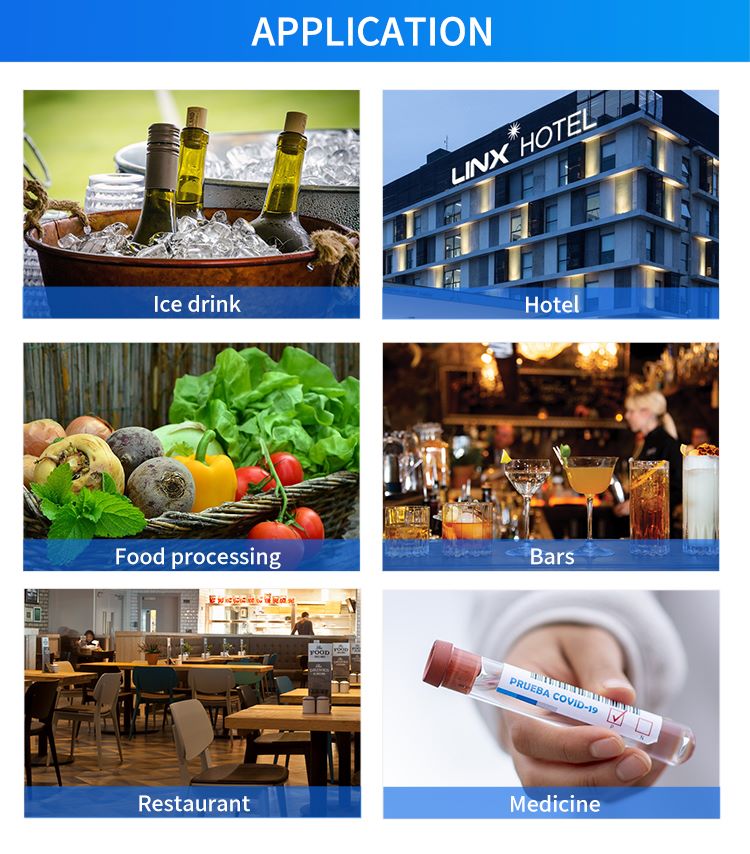

| Ice Tube Making Machine Application

Ice tube are widely used in food processing plant pre-cooling cooling, meat and poultry processing plants, fisheries, aquatic fruits and vegetables preservation and transportation.

The 15-ton integrated tube ice machine has become an ideal ice-making solution for many industries due to its high efficiency, low energy consumption, and easy maintenance. If you are looking for an ice-making equipment that can meet large capacity requirements and has energy-saving and environmental protection,15ton Integrated tube ice maker machine will be a good choice.

| Icemedal Integrated Tube Ice Machine Features:

1.Integrated Design: It adopts a compact integrated design that integrates ice making, ice storage and transportation functions, greatly saving plant space and simplifying the installation process.

2.Customization Service: We supports the adjustment of ice tube sizes of various specifications to meet the special needs of different industries. At the same time, additional services such as customized appearance design and logo printing can also be provided according to customer needs.

3.Better ice quality :Tube ice is more uniform and less crushed ice

4.Smaller space :Less shipping costs and constructing costs, The 15ton intedrated tube ice maker floor space is usually reduced by 30%~50% compared to split-type equipment

5. Easier installation (Less installing time and costs, reduce the risk of damage due toimproper operation)

| Integrated Tube Ice Machine Parameters

| Model | IMT5 | IMT10 | IMT15 | IMT20 | IMT30 |

Ice output | 5t/24hrs | 10t/24hrs | 15t/24hrs | 20t/24hrs | 30t/24hrs |

| lce tube diameter | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional | Φ22,Φ29,Φ35,Φ42 is optional |

| Cooling Capacity | 52.5kw | 82kw | 123.9kw | 165.2kw | 247.8kw |

| input power | 20.95kw | 37.2kw | 51.9kw | 64.5kw | 106.8kw |

| Compressor input power | 17.3kw | 31.9kw | 45.2kw | 52.8kw | 102.6kw |

| lce cut reducer input power | 0.75kw | 0.75kw | 1.5kw | 1.5kw | 2.2kw |

| Water pump input | 1.1kw | 1.5kw | 2.2kw | 2.2kw | 4kw |

| Ice machine Weight | 1600kg | 2750kg | 4000kg | 4800kg | 6200kg |

| Ice Machine Size | 1800*1620*2450 | 2400*2250*3200 | 2400*2250*4200 | 2500*2250*5437 | 2500*2250*6090 |

| Ice Tube Making Machine Application

Ice tube are widely used in food processing plant pre-cooling cooling, meat and poultry processing plants, fisheries, aquatic fruits and vegetables preservation and transportation.